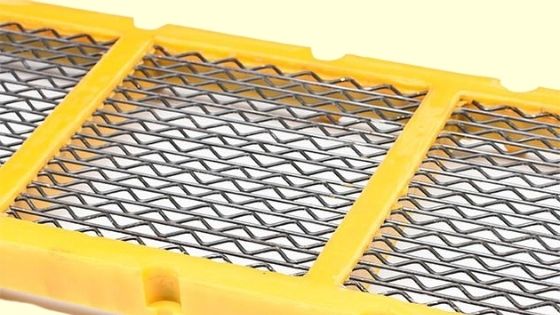

Harp screens are ideal for screening fines and other rigid materials with your mobile screening plant (also known as piano wire screens). This screen media is still known to be the most efficient and productive globally, and it solves more difficulties than not when it comes to damp and sticky materials.

Harp screens, on average, screen 80 percent more than similar aperture was woven wire mesh, resulting in more tons per hour of production. There is highly minimal material build-up on harp screens since there are no cross-wires. Hence there are no corners for fines to start piling up from. The diameter of the wire is usually less than that of wire mesh, allowing particles to take hold on a smaller surface area.

If you’re screening challenging materials using woven wire mesh, you can be experiencing screen blinding and pegging. Consider utilizing a harp screen to get a more efficient result when working with sticky and moist aggregate. Unlike woven mesh, harp screens are composed of individually tensioned wires that run straight and hook to hook.

During the screening process, these wires move independently and cut through the material, resulting in increased output rates and a higher proportion of open space.

There are situations when a harp screen isn’t necessary, such as when massive materials fall straight on the harp.

Because they are not meant for impact, you will need to remove the oversized goods or protect the above deck. Long flat pieces can result in oversize in the finished product depending on what material you’re screening and your product sizing needs.

The harp is fitted appropriately to ensure the most extended life from the screen. This means the tension bar must be in the hook’s back before tension, and the profiles are correctly placed onto the stringers. Recheck the screen tension after four to six hours of use from installation and make any required adjustments.

Will wire screens stretch?

Within the first two weeks of usage, the majority of screen tension changes are made. Will wire screens stretch? As a result of their construction and use, and hence lose their initial tension. These screens’ tension is checked regularly.

The hooks are built to last while still being simple to install. Plastic profiles are available in a round shape to fit over round top capping rubber or a square profile to fit directly over your stringer rail. Because the wire used to make Flomax harp screens has a higher carbon content (about 30%) than regular woven mesh, it has the most extended wear life.

The highest production screens on the market are Flomax harp screens. AEG offers harp/piano wire screen cloths for Power screen, Terex Finlay, Precision screen, McCloskey, Metso, Sandvik, and Kee track mobile screening plants, to name a few. Within the following parameters, AEG can produce practically any harp screen specification:

- The overall dimensions can be any combination of 3300mm (length) and 1830mm (width) inside hooks.

- The apertures range from 1.0 to 16 millimeters. Almost any aperture is created.

- Carbon steel and stainless-steel wire diameters range from 0.7mm to 2.5mm.

- The hooks can be adjusted to fit any tension bar configuration.

This is all about Harp Screens. It is just a brief about the product and nothing much. If you want to learn more about it before making a purchase, you can always contact the manufacturers to clear all your doubts.