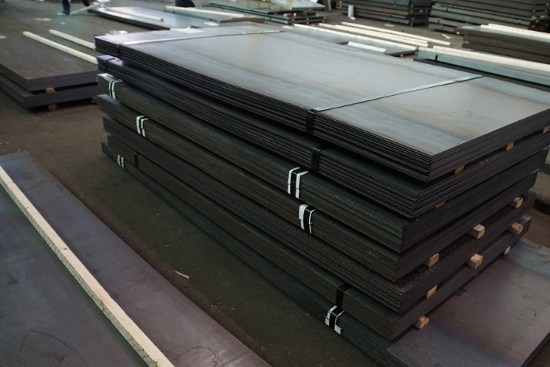

Alloy steel is steel that is usually alloyed with different elements in order to enhance the mechanical properties. In addition, it is alloyed with one or two elements in order to find huge applications in industry such as manganese, titanium, nickel, silicon, chromium and so on. Alloy Steel Plates A387 find huge benefits in the industry due to its low cost, extensive availability, ease of use and enhanced mechanical properties.

When compared to carbon steels, alloy steel has the highest responsiveness in the field of heat and mechanical treatments. Alloy steel is strong, hard, corrosion resistance as compared to ordinary carbon steel. Moreover, alloy steel finds a huge application that needs high strength, toughness and wear resistance is ideally suited than ordinary carbon steel. In addition, alloy steels are greatly used in the boiler industry due to its inexpensive, easily available, and easily welded to the desired shape, corrosion resistant and so on. It has the capacity to provide satisfactory service to the industry for many years.

Strong when compared to carbon steel:

When compared to carbon steel, alloy steel is highly strong and hard and extremely demanded in the aerospace and nuclear industries. For example, it finds huge benefits in the place of electric motors. Alloy steel can be sustained in the industry with the help of other elements like silicon and manganese in order to improve the weldability. It has high mechanical properties and can be easily achievable by the use of additional elements like nickel, chromium, molybdenum, and vanadium.

Alloy steel is one of the most flexible and adaptable steels in the world, having a wide range of physical properties and some specifications, they used in a variety of power industries. It is highly demanded its superior performance under high-pressure environments.

How do other elements help to form Alloy Steel Plates A387?

- Aluminum – helps to remove some elements like oxygen, sulfur, and phosphorus from steel.

- Bismuth – helps to enhance the machinability.

- Chromium – helps to increase corrosion and wear resistance, rigidity, and robustness.

- Cobalt – helps to improve the stability

- Copper – helps to improve hardening properties and corrosion resistance.

- Manganese – helps to enhance the hardness, ductility, wear resistance, and high-temperature strength.

- Molybdenum – helps to reduce the carbon concentration

- Nickel – helps to reduce the oxidation content.

- Silicon – helps to increase the strength and magnetism.

Alloy Steel Plates A387:

Alloy Steel Plates A387 is tremendous alloy steel and possess high yield strength, where it needs with high temperature. It is usually produced with the combination of Chromium-Molybdenum in order to enhance the tensile strength under high temperature. In addition, A387 is better than carbon steel because of its high responsiveness in order to use in the mechanical treatments. They are formed by the combination of different elements like chromium, molybdenum, and many others in order to moulds in an industry where strong, hardness and weldable are needed. Here are some of the huge benefits of Alloy Steel Plates A387 is listed below,

- Durability

- Hardness and toughness

- High performance

- Good weldability

- High corrosion resistance